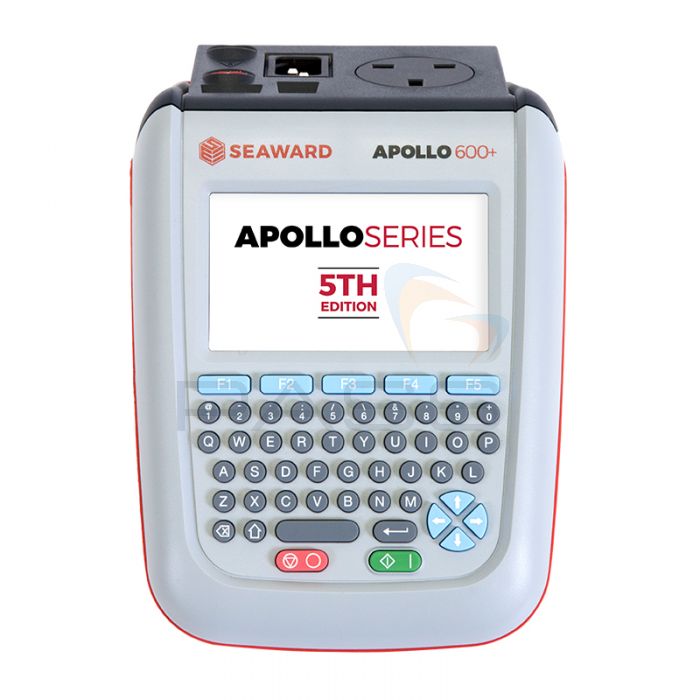

Seaward Apollo 600+ PAT Tester - New 5th Edition

- 5th Edition compliant

- Onboard digital, colour camera with flash

- Optimised for health and safety applications

The Seaward Apollo 600+ 5th Edition PAT Tester has been optimised for maintaining compliance with the IET 5th Edition Code of Practice and performing health and safety checks, making it the most sophisticated PAT tester in Seaward’s Apollo+ range. As such, the Seaward Apollo 600+ PAT Tester includes a number of features and capabilities not found on the Apollo 400+ or the Apollo 500+, including:

- A colour camera with flash: this integrated digital camera allows the user to take images which serve as evidence of visual inspections. Using the compatible Seaward PAT Guard 3.4 Software (see below) these images may be tagged against the record pertaining to the appliance. In addition to this photographs (up to 2000) may be stored on the PAT tester itself.

- A universal risk assessment tool: this tool is built into the Apollo 600+ and facilitates the unit’s ability to record hazards, calculate risk scores and plan and document corrective actions.

- Onboard reports for fire detection and emergency lighting: these report templates make the Seaward Apollo 600+ PAT Tester ideal for health and safety management applications.

The Seaward Apollo 600+ PAT Tester also includes the most extensive memory of all the models in this series. It is able to hold up to 50 000 appliance records and 2000 images, ensuring complete traceability. Furthermore, these results may be transferred straight to a USB flash drive, a capability that is unique to the Apollo 600+. However, like the other models, this instrument can also send information to a PC through a USB cable or to an Android device via Bluetooth.

Like the Apollo 400+ and 500+, the Apollo 600+ is able to conduct the following tests:

- Low current earth continuity test (with Zap circuit) guaranteeing accurate measurements

- Insulation resistance

- IEC lead test

- Protective conductor current

- Touch current

- Load power/current

- Alternative leakage current

- RCD test

- Power Socket Test

- Point to point fixed appliance testing for earth continuity and insulation resistance

- Class 2 FE (5th edition update)

Furthermore, this model also includes a risk-based retest period calculator allowing the user to ascertain when an appliance should next be tested according to the IET 5th Edition Code of Practice. Moreover, the user can create up to 100 customised electrical test and visual inspection sequences.

The Seaward Apollo 600+ PAT Tester is an updated version of the Seaward Apollo 600 PAT Tester and as such features improvements to its hardware, firmware and software compatibility. Please see the video below for an overview of the Seaward Apollo 600+ PAT Tester.

Software Compatibility

The results gathered by the Seaward Apollo 600+ PAT Tester may be analysed and organised into reports using the compatible Seaward PAT Guard 3.4 Software (sold separately). This software includes Time Manager which has been designed to assist the user with managing a team of workers.

In addition to this, the Seaward Apollo 600+ PAT Tester is also compatible with QR scanners and printers (more information below), as well as Bluetooth.

Firmware

Read and print 2D QR data codes containing information such as the asset ID, the site, the location, the last test date and the next test date.

To accommodate these capabilities the Seaward Apollo 600+ PAT Tester must be used with the following OPTIONAL accessories:

- Seaward Test ‘n’ Tag Elite 2 Printer – used to print labels containing QR data codes.

- Seaward Bluetooth 2D Elite Barcode Scanner – facilitates quick retesting using the Apollo 600+. Scan QR codes in order to determine previous test information; these details are automatically used to populate the relevant fields in the Apollo 600+’s test setup.

- FREE Seaward QR Data Viewer App – scan QR codes and send information via email.

The Seaward Apollo 600+ PAT Tester also includes the following:

- User permissions for Bluetooth

- An option to delete unwanted results

- ‘View Data Menu’ is equipped with a more advanced search function able to filter results according to a variety of specifications, including the PASS/ FAIL status of each test. It has also been designed to scroll more quickly.

- ‘After Test’ function has been expanded to include an option for the automated printing of test results

- ‘Worst’ and ‘Last’ result options have been added to the leakage test settings

- Predictive drop-down lists can be tailored to the user’s needs by deleting unnecessary options

- Download information to an Android device using USB on-the-go technology

- Downloaded files can be named using unique identifiers, ensuring that they are easier to find

- The newly added socket outlet test allows the user to measure main voltage and outlet wiring polarity

- Asset ID is displayed on all test screens

- Addition of a Review Step allows the user to check test information before adding any final comments

- 2020 5th Edition update includes a brand-new set of test sequences including Class 2 FE and other new tests as per the 5th Edition

The new 5th Edition firmware will also be available to download free of charge for current Apollo users who will be able to update to the new firmware and benefit from the new test features.

Note: in existing Apollos touch current tests will be limited by the hardware to 3.5mA.

Hardware

The design of the Seaward Apollo 600+ PAT Tester has been updated to improve the practicality and efficiency of the instrument. To this end, it includes tests leads featuring stronger PVC insulation and robust probes, ensuring that the Seaward Apollo 600+ PAT Tester is suitable for more demanding applications.

In addition to this, the Apollo 600+ can be powered both by a battery and mains power. The battery pack supplied with this unit is removable, interchangeable and rechargeable, ensuring that downtime is kept to a minimum.

Like its predecessor, the Apollo 600, the Seaward Apollo 600+ PAT Tester features a colour, high-definition display and QWERTY keyboard, maintaining its ease-of-use.

The 2020 5th edition hardware update also allows for the increase in protective and touch leakage limits to 5mA rather than 3.5m.A.

The Seaward Apollo 600+ PAT Tester is a versatile, adaptable and practical plug-and-play PAT tester, optimised for testing high volumes of appliances and conducting health and safety inspections.

Seaward Apollo 600+ PAT Tester Key Features

- 5th Edition update of the Seaward Apollo 500+

- Brand-new set of test sequences including Class 2 FE and other new tests as per the 5th Edition

- Most advanced PAT tester in Seaward’s Apollo+ Series

- Optimised for performing health and safety checks and maintaining compliance with the IET 5th Edition Code of Practice

- Digital, colour camera with flash

- Capture images to serve as evidence of visual inspections

- Universal Risk assessment tool – records hazards, calculates risk scores, plans and documents corrective actions

- Onboard reports for fire detection and emergency lighting

- Extensive memory – holds up to 50 000 test records and 2000 images

- Results may be transferred to a USB flash drive

- Send information to a PC using a USB cable

- Send information to an Android device via Bluetooth

- Low current earth continuity test (with Zap circuit) guaranteeing accurate measurements

- Insulation resistance

- IEC lead test

- Protective conductor current

- Touch current

- Load power/current

- Alternative leakage current

- RCD test

- Power Socket Test

- Point to point fixed appliance testing for earth continuity and insulation resistance

- Integrated risk-based retest period calculator

- Create up to 100 user-customised electrical test and visual inspection sequences

- An updated version of the Apollo 600

- Compatible with Seaward’s PAT Guard 3.4 Software with Time Manager

- Compatible with QR scanners and printers

- Bluetooth compatible

- When used with selected OPTIONAL accessories, the Apollo 600+ can be used to read and print QR codes

- User permissions for Bluetooth

- An option to delete unwanted results

- ‘View Data Menu’ is equipped with a more advanced search function able to filter results according to a variety of specifications, including the PASS/ FAIL status of each test.

- ‘After Test’ function has been expanded to include an option for the automated printing of test results

- ‘Worst’ and ‘Last’ result options have been added to the leakage test settings

- Predictive drop-down lists can be tailored to the user’s needs by deleting unnecessary options

- Download information to an Android device using USB on-the-go technology

- Downloaded files can be named using unique identifiers, ensuring that they are easier to find

- Socket outlet test allows the user to measure main voltage and outlet wiring polarity

- Asset ID is displayed on all test screens

- Addition of a Review Step allows the user to check test information before adding any final comments

- Hardware update improves the practicality of the Apollo 600+

- Supplied with test leads featuring stronger PVC insulation

- Supplied with robust probes

- Can be powered by both battery power and mains power

- Supplied with a removable, interchangeable, rechargeable battery pack

- Colour, high-definition display

- QWERTY keyboard

- Fast start-up

- An easy-to-use, versatile, adaptable and practical plug-and-play PAT tester

- Optimised for testing large volumes of appliances and conducting health and safety inspections

Operating the Seaward Apollo+ PAT Testers

The following videos offer a brief introduction to using some of the Seaward Apollo+ PAT Testers' features.

Switching on the Bluetooth Setting

Setting Up a Printer to Work with the Apollo+

Connecting a Printer to the Apollo+

Pairing a 1D Scanner with the Apollo+

Pairing a 2D Scanner with the Apollo+

Uploading a Company Logo to the Apollo+ for use on Printing Labels

Uploading a Background Image to the Apollo+

Changing the Background Image on the Apollo+

Deleting a Single Asset from the Apollo+

Deleting Test Results from the Apollo+

Confirming Firmware and Calibration Information on the Apollo+

Updating Firmware on the Apollo+

Factory Resetting the Apollo+

Whats Included?

- Seaward Apollo 600+ PAT Tester

- Professional Carry Case

- Red Test Lead 1.2m with Alligator Clip

- Black Test Lead 1.2m with Alligator Clip

- IEC Extension Lead, 0.5m

- Black Mains Lead

- USB Download Lead

- Apollo+ Check Box

Offers

- PASS Training Online Course with Exam, Pass & Fail Labels - PTPROMO7, typically £93.27

Seaward Apollo 600+ Technical Specifications

| Earth Continuity | |

| Test Current | ±200mA DC |

| Display Range | 0.01 to 19.99Ω |

| Pass Value | User defined |

| Insulation Resistance | |

| Test Voltage | 500V / 250V DC @ 1mA nominal |

| Display Range | 0.01MΩ to 19.99MΩ |

| Pass Value | User defined |

| IEC Lead Test | |

| Test Voltage | 5V AC nominal |

| Test | Live/neutral checks for o/c, s/c and crossed |

| Protective Conductor Current/Load | |

| Test Voltage | Supply voltage, maximum load current 16A |

| Display Range | 0.01mA to 19.99mA |

| Pass Value | User defined |

| Touch Current | |

| Test Voltage | Supply voltage, maximum load current 16A |

| Display Range | 0.00 to 5mA |

| Pass Value | User defined |

| Load Power/Current | |

| Test Voltage | 230V + 10%, maximum load current 16A |

| Test Duration | Programmable up to a maximum of 255s depending on load. i.e. max duration is reduced for high loads |

| Display Range | 0.00kVA to 4.00kVA 0.00A to 16.00A |

| Alternative Leakage Current | |

| Test Voltages | >25V AC <50V AC |

| Display Range | 0.00mA to 19.99mA |

| Pass Value | User defined |

| RCD Test | |

| Test Voltage | 230V + 10%, -15% |

| Test Current | 15mA/30mA rms sinusoidal |

| Display Range | 0ms to 2000ms |

| Test Method | Internal isolation to avoid tripping distribution board RCDs |

| Power Socket Test | |

| Voltage Range | 207V to 253V AC |

| Indication of Voltage Potential | Line potential phase to earth Line potential phase to neutral Line potential neutral to earth |

| General Specifications | |

| Memory Size | 50000 records + 2000 photos |

| Weight | 1.5kg |

| Dimensions | 230 x 150mm x 100mm |

| Power Source | Mains or rechargeable battery pack |

Comparison Chart

| General Features | 600+ | 500+ | 400+ |

| Battery & mains powered | • | • | • |

| Colour screen & QWERTY keypad | • | • | • |

| Large internal memory | up to 50,000 records and 2,000 photos | up to 10,000 records | up to 2,000 records |

| Bluetooth scanner & printer compatible | • | • | • |

| Password controlled user accounts | • | • | |

| Set up multiple user accounts with varying levels of privileges | • | • | |

| Clone facility to set up multiple testers | • | • | |

| Checkbox supplied as standard | • | • | |

| Test Inspection Features | 600+ | 500+ | 400+ |

| Auto-increment asset ID | • | • | |

| PAT Setup option to allow for custom menus | • | • | |

| Enter asset description after test using the keypad or barcode scanner | • | • | • |

| Comprehensive electrical safety test features | • | • | • |

| Point to point measurement (Rpe & IR) | • | • | Optional accessory required |

| User configurable electrical test/visual inspection sequences | 100 | 100 | 25 |

| User set sites & locations | 100 | 100 | 50 |

| Risk-based retest period calculator | • | • | |

| User definable comments lines against test records | 4 | 4 | |

| Configurable checklists for any workplace test or inspection (user tests) | • | • | |

| Onboard camera | • | ||

| Universal risk assessment | • | ||

| Health & safety certificates | • | ||

| Data Transfer | 600+ | 500+ | 400+ |

| 1D and 2D Scanner connectivity | • | • | Reads 1D Data Only |

| Read QR code (2D) labels with 2D scanner | • | • | |

| RFID reader connectivity | • | • | |

| Print Pass & Fail labels with 1D barcode | • | • | • |

| Print Pass & Fail labels with QR code (2D) | • | • | |

| Add your company logo to labels (on large 1D labels only) | • | • | |

| Select from various label formats to print | 6 | 6 | 6 |

| Download to PC via USB cable | • | • | • |

| Data Transfer via USB flash drive | • | ||

| Filter results to be downloaded | • | • | • |

| Upload previous results to the tester for a retest | • | • |