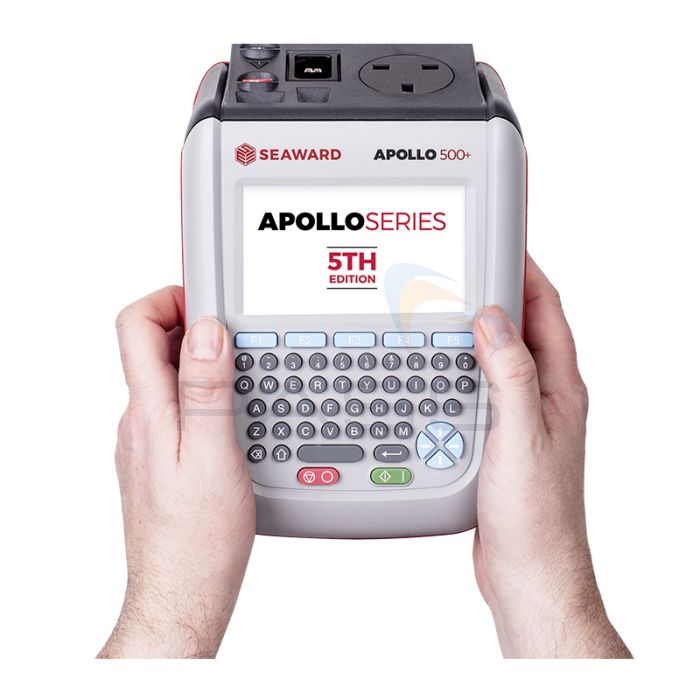

Seaward Apollo 500+ PAT Tester - New 5th Edition

- Integrated electrical risk assessment tool with retest calculator

- includes Class 2 FE and an increase in protective and touch leakage limits to 5mA

- 5th Edition 2020 update

The Seaward Apollo 500+ 5th Edition PAT Tester is an updated version of Seaward’s Apollo 500+ PAT Tester and is compliant with the new code of practice, this includes Class 2 FE, protective and touch leakage limits to 5mA (as the new code of practice now requires testers to have a pass-fail limit of 5mA for all leakage tests) as well as other new tests as per the 5th Edition.

The new 5th Edition firmware will also be available to download free of charge for current Apollo users who will be able to update to the new firmware and benefit from the new test features.

Note: in existing Apollos touch current tests will be limited by the hardware to 3.5mA.

The 500+ is optimised for conducting extensive tests on portable appliances. Its large memory (capacity to store up to 10 000 records) makes it particularly well suited to high volumes of PAT testing. Please see the following video for an introduction to the Apollo 500+.

The Seaward Apollo 500+ PAT Tester includes the following test features:

- Low current earth continuity test with Zap circuit, guaranteeing accurate measurements

- Insulation resistance

- IEC lead test

- Protective conductor current

- Touch current

- Load power/current

- Alternative leakage current

- RCD test

- Power Socket Test

- Class 2 FE

This instrument is also capable of performing point-to-point fixed appliance testing for earth continuity and insulation resistance. These safety tests ensure compliance with the IET 4th Edition Code of Practice and can be organised into up to 100 user-customised electrical test and visual inspection sequences. This tester also includes an integrated electrical risk assessment tool with retest calculator, allowing the user to determine suggested retest periods.

In addition to this, the Seaward Apollo 500+ PAT Tester is able to read and produce 2D QR codes. These capabilities are facilitated by additional accessories:

- The Seaward Test ‘n’ Tag Elite 2 Printer allows the user to print labels with a unique QR data code.

- Seaward’s new Bluetooth 2D Elite Barcode Scanner can be used to scan QR codes in order to access information regarding previous tests, thereby automatically populating the Apollo 500+'s relevant test fields, allowing the instrument to perform retests quickly and easily.

- Available for Android and iOS, Seaward’s FREE QR Data Viewer App also facilitates the scanning of QR codes allowing the user to view test information which can then be shared via email.

The Seaward Apollo 500+ PAT Tester’s ability to read, print and utilise information in QR data codes is made possible as a result of its updated firmware. For further information regarding the firmware, hardware and compatibility updates pertaining to the Seaward Apollo 500+ PAT Tester, please see below.

Firmware Features

The firmware on the Apollo 500+ has made it versatile, practical and efficient for quick, mid/high volume PAT Testing.

- User permissions for Bluetooth

- An option to delete particular results

- The ‘View Data Menu’ has been improved to facilitate faster scrolling and a more effective search. The user is able to filter results according to various specifications, including the PASS/ FAIL status of each test.

- The ‘After Test’ function includes the option to automatically print test results.

- Leakage test settings include options for ‘Worst’ and ‘Last’

- Items can be deleted from the predictive drop-down menu options allowing the user to tailor the interface to his/her requirements

- The inclusion of USB on-the-go technology allows the user to download information directly onto an Android device

- Downloaded files may be named using unique identifiers, ensuring that they are easy to locate

- Measure main voltage and outlet wiring polarity using the newly added socket-outlet test

- Asset ID is displayed on each test screen

- Review Step allows the user to check test details before adding any final comments

Software Compatibility

In addition to the Bluetooth, scanner and printer compatibility of this tester, it is also compatible with the Seaward’s PAT Guard 3.4 Software with Time Manager (sold separately). This software allows the user to review results, create reports and manage teams of workers.

Hardware

The Seaward Apollo 500+ PAT Tester’s firmware and software compatibility improve its versatility, whilst its hardware update improves the instrument’s practicality.

The Seaward Apollo 500+ PAT Tester includes a removable, interchangeable, rechargeable battery pack; however, it may also be powered using a mains supply, ensuring that downtime is kept to a minimum.

Furthermore, the test leads supplied with this unit feature stronger PVC insulation and the probes have been designed to be sturdier, making them better suited to demanding usage.

In other respects, the Seaward Apollo 500+ PAT Tester’s design is similar to that of its predecessor, the Seaward Apollo 500/+ PAT Tester. It continues to include colour, high-definition display and QWERTY keyboard, ensuring that it remains simple to use.

The Seaward Apollo 500+ PAT Tester is an easy-to-use, plug-and-play PAT tester, ideal for testing high volumes of portable appliances. Its updated design ensures that it is practical, versatile and adaptable.

Seaward Apollo 500+ PAT Tester Key Features

- 5th Edition update of the Seaward Apollo 500+

- Brand-new set of test sequences including Class 2 FE and other new tests as per the 5th Edition

- Ideal for conducting tests on large volumes of portable appliances

- Extensive memory – capacity to store up to 10 000 records

- Low current earth continuity test with Zap circuit, guaranteeing accurate measurements

- Insulation resistance

- IEC lead test

- Protective conductor current

- Touch current

- Load power/current

- Alternative leakage current

- RCD test

- Power Socket Test

- Point- to- point fixed appliance testing for earth continuity and insulation resistance

- Safety tests ensure compliance with the IET 5th Edition Code of Practice

- Up to 100 user-customisable electrical test and visual inspection sequences may be created

- Integrated electrical risk assessment tool with a retest calculator for determining suggested retest periods

- Can read and produce QR codes using additional accessories

- Seaward Test ‘n’ Tag Elite 2 Printer facilitates the printing of labels with unique QR data codes

- Seaward Bluetooth 2D Elite Barcode Scanner can be used to scan QR codes for test information, allowing the Apollo 500+ to perform retests quickly and easily

- Seaward’s FREE QR Data Viewer App (for Android or iOS) can be used to scan QR codes and subsequently share test information via email

- The firmware update facilities the Apollo 500+'s QR reading and printing capabilities and expands the Apollo 500+’s versatility, adaptability and efficiency

- User permissions for Bluetooth

- An option to delete particular results

- Items can be deleted from the predictive drop-down menu options allowing the user to tailor the interface to his/her requirements

- The inclusion of USB on-the-go technology allows the user to download information directly onto an Android device

- Downloaded files may be named using unique identifiers, ensuring that they are easy to locate

- Measure main voltage and outlet wiring polarity using the newly added socket outlet test

- Asset ID is displayed on each test screen

- Review Step allows the user to check test details before adding any final comments

- Bluetooth, scanner and printer compatibility

- Remote data transfer from the field to the office via Bluetooth

- Compatible with Seaward’s PAT Guard 3.4 software with Time Manager (sold separately)

- Hardware update improves the Apollo 500+’s practicality

- Removable, interchangeable, rechargeable battery pack

- Can be powered using a mains supply

- Test leads feature stronger PVC insulation

- Test probes are sturdier

- Colour, high-definition display

- QWERTY keyboard

- Fast start-up

- An easy-to-use, versatile, adaptable and practical plug-and-play PAT tester

Operating the Seaward Apollo+ PAT Testers

The following videos offer a brief introduction to using some of the Seaward Apollo+ PAT Testers' features.

Switching on the Bluetooth Setting

Setting Up a Printer to Work with the Apollo+

Connecting a Printer to the Apollo+

Pairing a 1D Scanner with the Apollo+

Pairing a 2D Scanner with the Apollo+

Uploading a Company Logo to the Apollo+ for use on Printing Labels

Uploading a Background Image to the Apollo+

Changing the Background Image on the Apollo+

Deleting a Single Asset from the Apollo+

Deleting Test Results from the Apollo+

Confirming Firmware and Calibration Information on the Apollo+

Updating Firmware on the Apollo+

Factory Resetting the Apollo+

Whats Included?

- Seaward Apollo 500+ PAT Tester

- Professional Carry Case

- Red Test Lead 1.2m with Alligator Clip

- Black Test Lead 1.2m with Alligator Clip

- IEC Extension Lead, 0.5m

- Black Mains Lead

- USB Download Lead

- Apollo+ Check Box

- UKAS Calibration Certificate

- Quick Start Guide

Offers

- PASS Training Online Course with Exam, Pass & Fail Labels - PTPROMO7, typically £93.27

Seaward Apollo 500+ Technical Specifications

| Earth Continuity | |

| Test Current | +/- 200mA DC |

| Display Range | 0.01 – 19.99Ω |

| Pass Value | User Defined |

| Insulation Resistance | |

| Test Voltage | 500V / 250V DC @ 1mA nominal |

| Display Range | 0.01MΩ - 19.99MΩ |

| Pass Value | User Defined |

| IEC Lead Test | |

| Test Voltage | 5V ac nominal |

| Test | Live / Neutral Checks for o/c, s/c and crossed |

| Protective Conductor Current/Load | |

| Test Voltage | Supply voltage, maximum load current 16A |

| Display Ranges | 0.01mA to 19.99mA |

| Pass Value | User Defined |

| Touch Current | |

| Test Voltage | Supply Voltage, maximum load current 16A |

| Display Range | 0.00 – 5mA. |

| Pass Value | User Defined |

| Load Power/Current | |

| Test Voltage | Supply Voltage, maximum load current 16A |

| Test Duration | Programmable up to a maximum of 255s depending on load. i.e. max duration is reduced for high loads |

| Display Range | 0.00kVA – 4.00kVA 0.00A – 16.00A |

| Alternative Leakage Current | |

| Test Voltages | >25Vac <50Vac |

| Display Range | 0.00mA to 19.99mA |

| Pass Value | User Defined |

| RCD Test | |

| Test Voltage | 230V +10%, -15% |

| Test Current | 30mA / 150mA rms sinusoidal |

| Display Range | 0ms - 2000ms (30mA), 0-40ms (150mA) |

| Test Method | Internal isolation to avoid tripping distribution board RCD |

| Power Socket Test | |

| Voltage Range | 207V – 253V AC Indicates configuration of voltage potential:- Line potential phase to earth Line potential phase to neutral Line potential neutral to earth |

| General | |

| Memory Size | 10000 Records |

| Weight | 1.5kg |

| Dimensions | 230mm x 150mm x 100mm |

| Power Source | Mains or Rechargeable Battery Pack |

Comparison Chart

| General Features | 600+ | 500+ | 400+ |

| Battery & mains powered | • | • | • |

| Colour screen & QWERTY keypad | • | • | • |

| Large internal memory | up to 50,000 records and 2,000 photos | up to 10,000 records | up to 2,000 records |

| Bluetooth scanner & printer compatible | • | • | • |

| Password controlled user accounts | • | • | |

| Set up multiple user accounts with varying levels of privileges | • | • | |

| Clone facility to set up multiple testers | • | • | |

| Checkbox supplied as standard | • | • | |

| Test Inspection Features | 600+ | 500+ | 400+ |

| Auto-increment asset ID | • | • | |

| PAT Setup option to allow for custom menus | • | • | |

| Enter asset description after test using the keypad or barcode scanner | • | • | • |

| Comprehensive electrical safety test features | • | • | • |

| Point to point measurement (Rpe & IR) | • | • | Optional accessory required |

| User configurable electrical test/visual inspection sequences | 100 | 100 | 25 |

| User set sites & locations | 100 | 100 | 50 |

| Risk-based retest period calculator | • | • | |

| User definable comments lines against test records | 4 | 4 | |

| Configurable checklists for any workplace test or inspection (user tests) | • | • | |

| Onboard camera | • | ||

| Universal risk assessment | • | ||

| Health & safety certificates | • | ||

| Data Transfer | 600+ | 500+ | 400+ |

| 1D and 2D Scanner connectivity | • | • | Reads 1D Data Only |

| Read QR code (2D) labels with 2D scanner | • | • | |

| RFID reader connectivity | • | • | |

| Print Pass & Fail labels with 1D barcode | • | • | • |

| Print Pass & Fail labels with QR code (2D) | • | • | |

| Add your company logo to labels (on large 1D labels only) | • | • | |

| Select from various label formats to print | 6 | 6 | 6 |

| Download to PC via USB cable | • | • | • |

| Data Transfer via USB flash drive | • | ||

| Filter results to be downloaded | • | • | • |

| Upload previous results to the tester for a retest | • | • |